homemade injection molding machine part 2

You can now remove the mold and separate the halves. Every mold is its own peculiar beast so are the basic components of the machine.

Pin By Arbi Oussama On 3d Printing Plastic Injection Moulding Machine Plastic Injection Molding Diy Molding

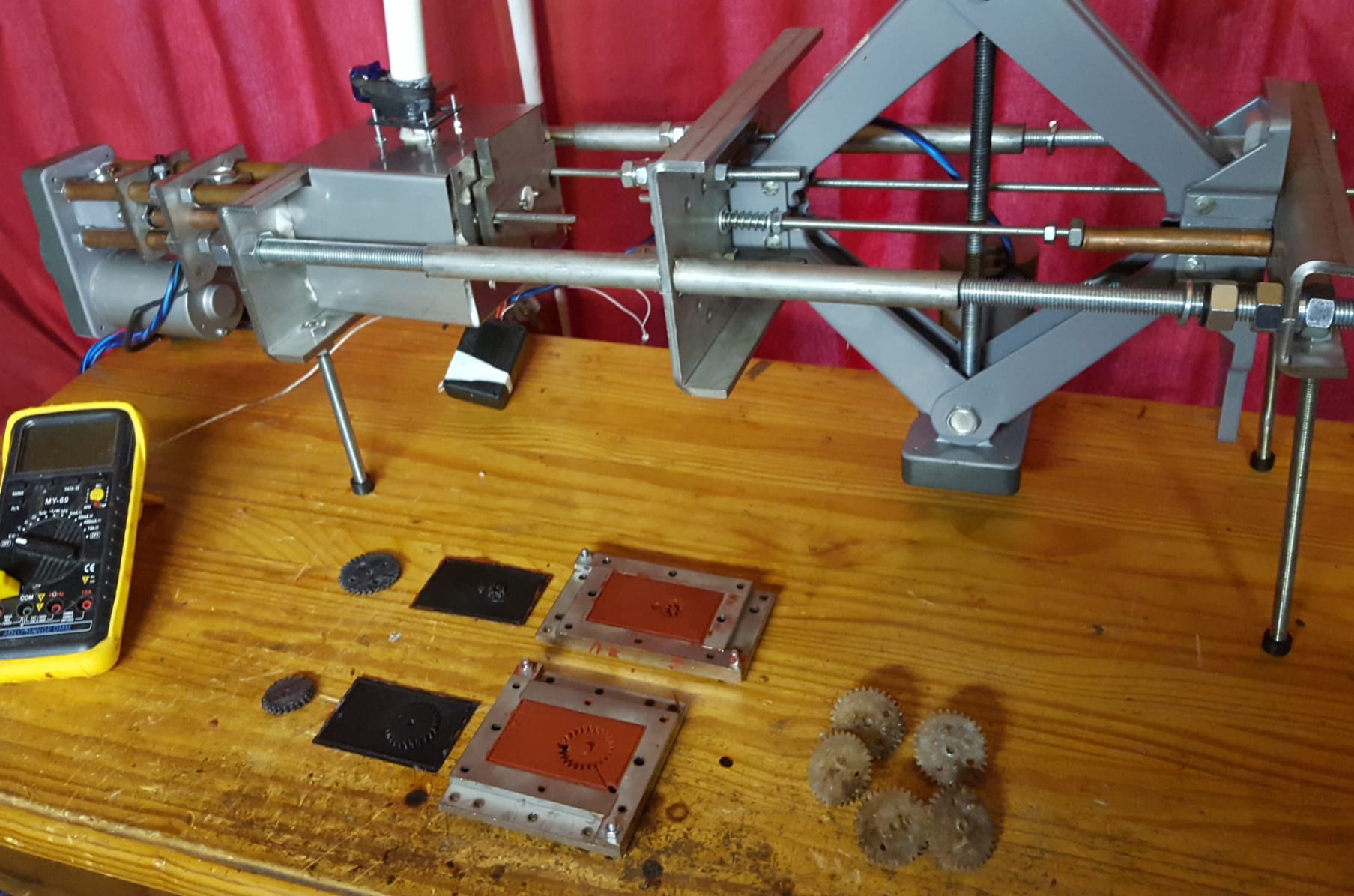

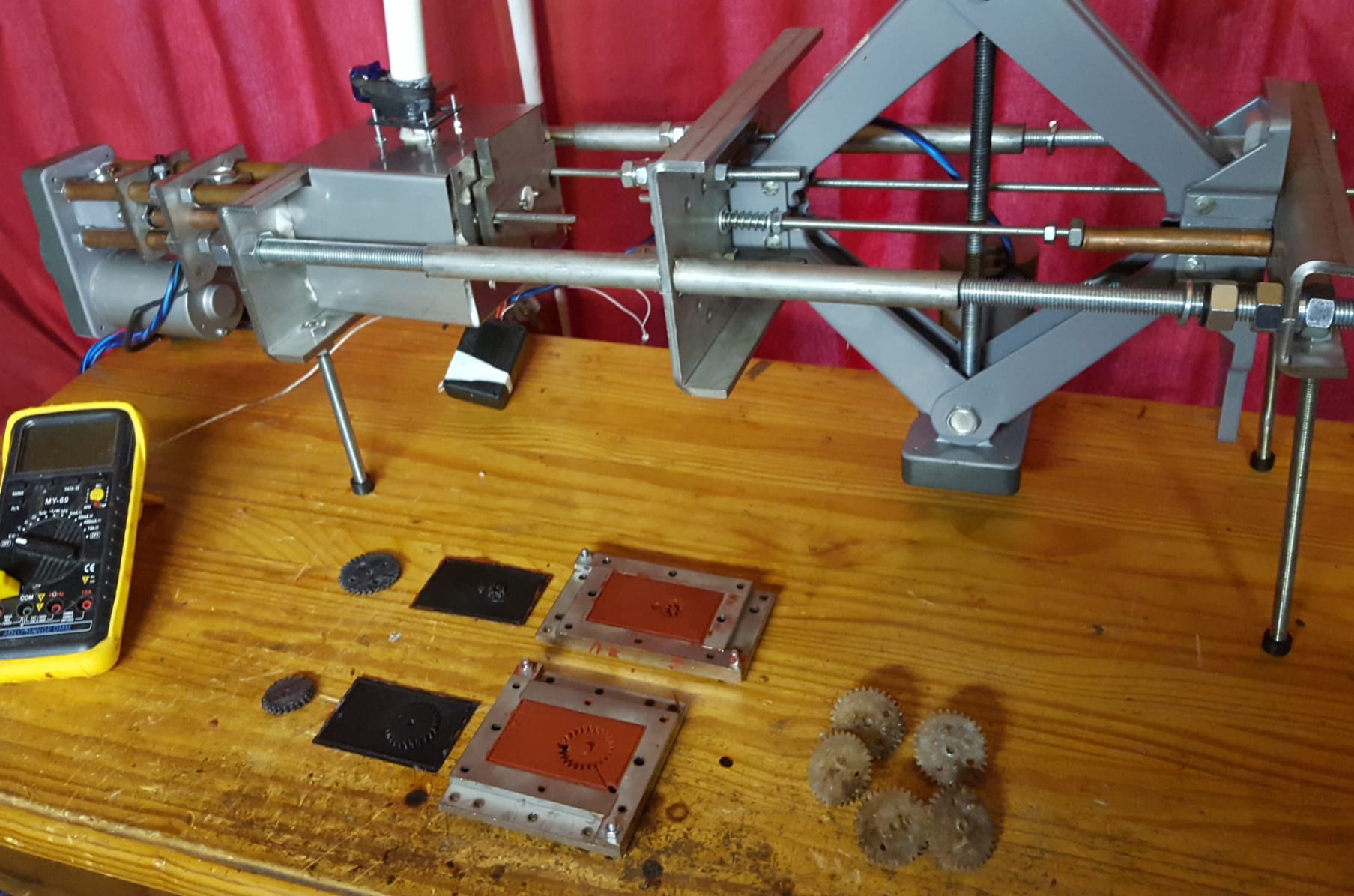

Part 1 shows the start of the build using an old tap burning machine a 60-volt power supply and a simple pulse generator.

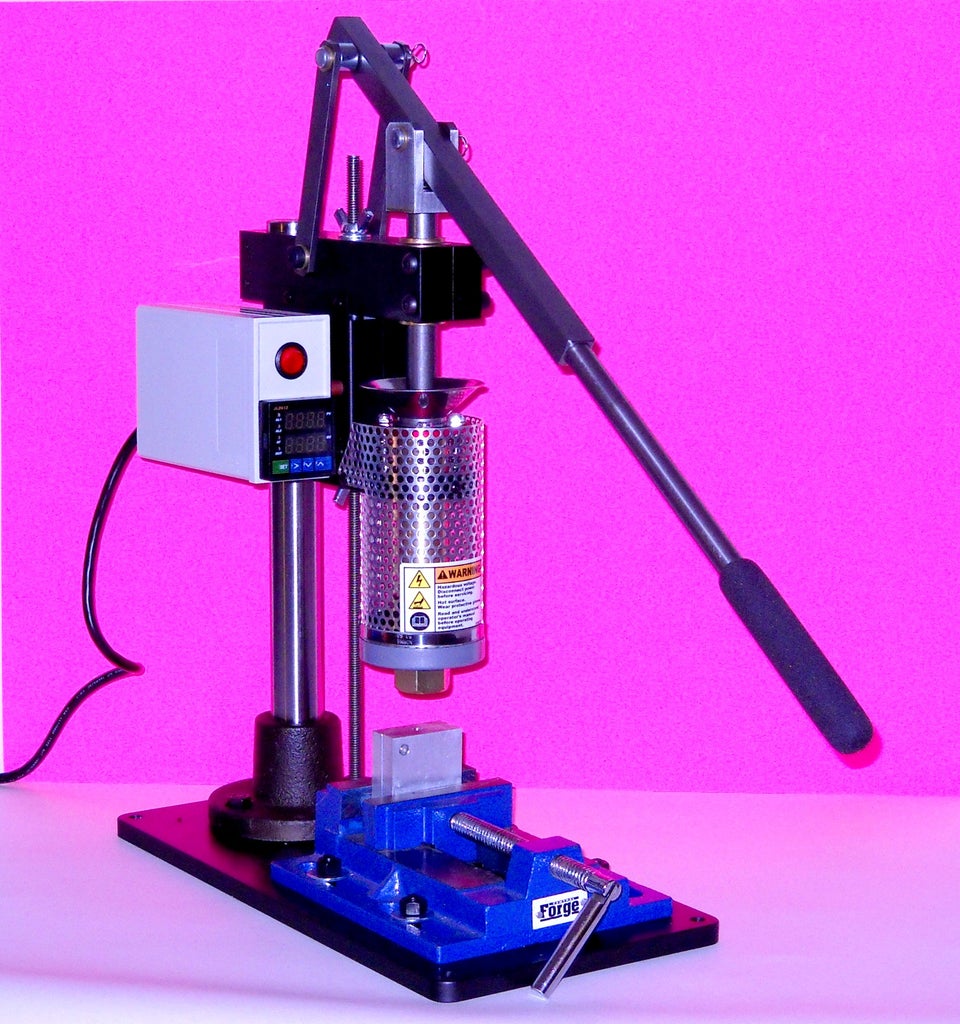

. Or by machining a desired cavity into an aluminum. Hold pressure on the handle for an extra few seconds. Small Injection Molding Machine from Galomb.

With a smooth linear motion push down on the handle and fill the mold. 17 kg x 12 19 kg 67 oz 105 4 Mold and Part Design Sprue Bushing A sprue bushing with a standard 2½ included angle approximately 42mm taper per meter 05 in. The FM3312 and FM3332 Fieldbus Modules in a sturdy metal housing are suitable for temperature measurement on injection molds or on injection barrels.

Up to 32 temperature channels can be contained in one industrial connector. B Make sure the sprue hole on top of the mold lines up exactly with the injection nozzle. Injection Molding Machine.

In this scenario ordering 1x unit of the toy car would cost 500050 ordering 2x units would cost 5001 and ordering 1000x units would cost 5500. This will help reduce shrinking of the plastic in the mold. Clamping force to hold mold closed.

To specify a machine break it down into its component parts. Packing pressure must be maintained until the gate solidifies. In all of the scenarios the mold accounts.

Most injection molders enter the business with small to mid-sized molding presses. The initial prototype had a problem with the molds being pushed up when they came together. Taper per foot should be used.

Pressure Pis used to pack the mold. Inexpensive homemade molds can be made using an epoxy or urethane resin. Retract the handle all of the way to remove the plunger and give access to load more pellets.

F Z A PdA 2πP ZR 0 rdr πR2P. This was enough to experiment with the basics of both the mechanical. Even pro shops will usually toss the initial few cycles as the machine warms up to operating temperatures.

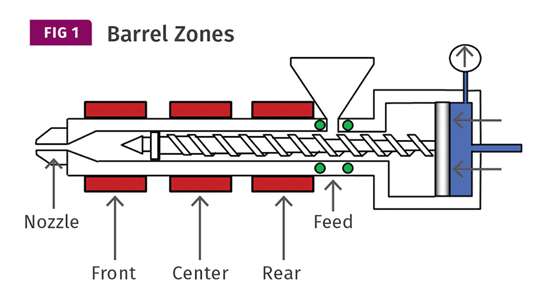

The barrel and the screw play an important role in achieving this goal. This seems to hold. These machines are designed to make it easy to prototype injection molded parts test molds and even do small production runs.

A Place a mold in the machine. A sheet of transite separating the hot and cold sections of the mold is recommended. It sure looks a lot more robust than the typical benchtop injection molding machines I had been seeing.

A brand new machine like the Galomb is circa 1500-1800. Build in flexibility because you do not know the future. The molding-machine barrel must be chosen so that the plastic resides inside long enough for the plastic to melt but not so long as to degrade.

Do not buy a machine for a single job. LNS Technologies Model 150A. Follow the Deming principle.

Heating the mold to just below the plastics melting temperature is highly recommended. In a custom operation try to give yourself some flexibility on either end of the spectrum to also mold somewhat smaller or larger parts. The larger the press the more it costs so the size of the majority of parts that will be molded is an important consideration.

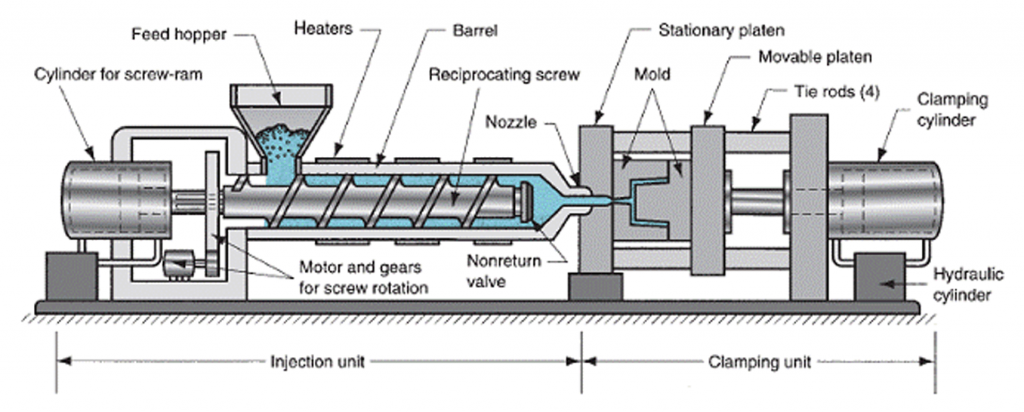

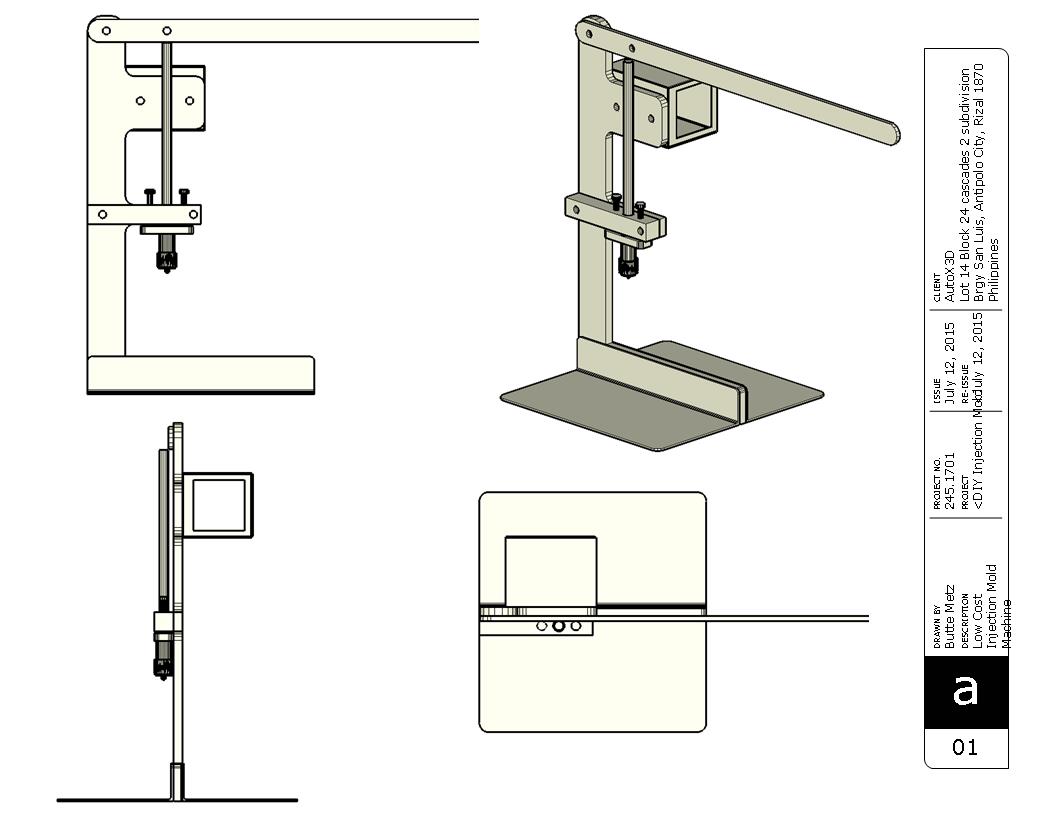

The melt must be homogeneous and not degraded. Bolzbrain wanted to bypass all of the heavy cutting welding and frame assembly work so hes built himself a DIY Injection Molding Press for. A Cylinder heats the material B Nozzle injects the melted material C Hopper material feeder D Mold material is poured into the mold cavity between two plates 3.

Next youll need an external air compressor to power the dual 2 pneumatic pistons. Using a lathe spindle to turn the screw which is itself a modified wood auger the small prototype which is not running a mold rapidly piles molten polypropylene on a table. A PID controller keeps the temperature relatively stable and heats the plastic pellets you can dump in the top.

Injection Molding Process Injection molding begins with resin pellets granules being poured into the hopper the entry point for the material. Injection Molding PACKING STAGE When the mold is full flow stops so there is no longer a pressure drop. Heating comes from two small 250W heaters with the.

Read on to see the best DIY and desktop injection molding machines. Feed the plastic raw material from the hopper into the barrel the plunger start to push the plastic raw material is pushed into a heating zone and then through the bypass shuttle the molten plastic through the nozzle into the mold cavity then water or oil run through the designed cooling system to cool down the mold. Operational reliability is additionally ensured by reverse polarity protection against phase voltage.

The people that use the equipment specify the equipment. He tweaked the mechanism to close with a downward motion by flipping the hinge design. C Clamp the mold in place by turning the vise handle clockwise.

Injection Molding Machine Part 2 The Extruder Screw Youtube Machine Parts Molding Injection Machine

Injection Molding Machine By Scorch Homemade Plastic Injection Molding Machin Plastic Injection Moulding Machine Plastic Injection Plastic Injection Molding

Diy Plastic Injection Molder Openbuilds

Diy Injection Molding How To Do Injection Molding In House

Full Automatic Homemade Injection Molding Machine

Build Your Own Desktop Injection Molding Machine Youtube

Go From 3d Printing To Desktop Injection Moulding Indiegogo

Diy All Electric Plastic Injection Molding Machine 3d Cad Model Library Grabcad

Homemade Injection Molding Machine Homemadetools Net

Injection Molding How To Set Barrel Zone Temps Plastics Technology

Injection Molding Molded Parts Plastic Injection Molding Process

Homemade Plastic Injection Machine Diy Youtube

Injection Molding Operation An Overview Sciencedirect Topics

Homemade Injection Molding Machine Part 1 Youtube

Make Your Own Injection Molding Machine Make

Homemade Plastic Injection Molding Machine Plastic Injection Plastic Injection Moulding Machine Diy Molding

Diy Plastic Injection Molding Machine Test Youtube

Home Plastic Injection Molding With An Epoxy Mold 7 Steps With Pictures Instructables